For more than 20 years, J.W. Treuth & Sons Inc., a kosher slaughterhouse based in Baltimore County, MD, has used a Model 5H from Oil Skimmers Inc. to remove fats, oil and grease (FOG) from kill-floor wastewater. The company recently purchased a new skimmer to replace the original, which, according to Vernon Treuth Sr., he purchased to correct FOG violations — the amounts of fats, oil and grease in to-be-disposed-of wastewater were above state-set limits.

As a kosher slaughterhouse, J.W. Treuth & Sons uses 25,000 gallons of water to butcher up to 100 cattle a day under kosher standards, which include precise methods for slaughter and processing. Much of the water is used for cleaning of the animal carcass, and cleaning and sterilization of equipment, tools, walls, floor and other materials that are part of the kill floor.

As a kosher slaughterhouse, J.W. Treuth & Sons uses 25,000 gallons of water to butcher up to 100 cattle a day under kosher standards, which include precise methods for slaughter and processing. Much of the water is used for cleaning of the animal carcass, and cleaning and sterilization of equipment, tools, walls, floor and other materials that are part of the kill floor.

Fats are a naturally abundant by-product of the ritualized slaughter, but if left in wastewater, they can cause contamination of public sewer systems. Mr. Treuth said he started looking for a way to reduce the FOG in kill-floor run-off after receiving three letters of violation from the state. At that time, he was using a settling tank with a hydro-sieve to remove FOGs; however, this was an inefficient method.

Cleveland-based Oil Skimmers Inc.’s Model 5H Oil Skimmer was an affordable and long-lasting solution for lowering FOG concentrations in the slaughterhouse wastewater. Mr. Treuth said his third-generation, family-owned business has been in compliance since installing the Model 5H, and has not received any non-compliance letters.

The Model 5H Oil Skimmer uses a unique floating-tube system. The closed-loop tube — made of flexible, specially formulated plastic — attracts oil but not water. The unit continuously draws the oil-covered tube through scrapers (which remove the oil) and returns the clean tube to the water surface to gather more oil.

For slaughterhouse operations, the Model 5H provides a low-maintenance solution that can run continuously or be easily turned off and on as needed. It is also compact, can be customized (mounting, location, etc.) and can start working immediately upon installation.

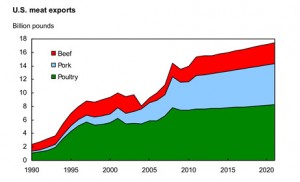

For all slaughtering operations, now is a good time to invest in valuable equipment such as a Model 5H Oil Skimmer. The industry is expected to grow into 2020, due to increased demand for exports of beef, pork and poultry, according to U.S. government projections.

For all slaughtering operations, now is a good time to invest in valuable equipment such as a Model 5H Oil Skimmer. The industry is expected to grow into 2020, due to increased demand for exports of beef, pork and poultry, according to U.S. government projections.

“The projected rise in U.S. meat and poultry exports over the next decade reflects the resumption of global economic growth, a depreciation of the U.S. dollar, and continued foreign demand for selected cuts and parts from the large U.S. market,” according to an analysis from the USDA.

For larger and/or non-kosher operations, Oil Skimmer systems are just as effective and can even be used to pre-treat wastewater before additional processing, i.e., DAF. Such pretreatment reduces maintenance needs and extends the life of filters and other machine components.

Additionally, Oil Skimmers, Inc. can custom-fit installations, according to vice president Jim Petrucci, and the company gives personalized service to each customer. The goal is to provide turnkey systems that can begin returning value immediately.

“You aren’t picking out something from a catalogue. We can adapt, modify, or even build from scratch.”