When water is used in an industrial process for manufacturing, cooling or washing, it often combines with contaminants (solids, oil, grease, fats, etc.). Before this water can be re-used within your facility or prepared for discharge into the municipal sewer system, it must first be cleaned of the oil.

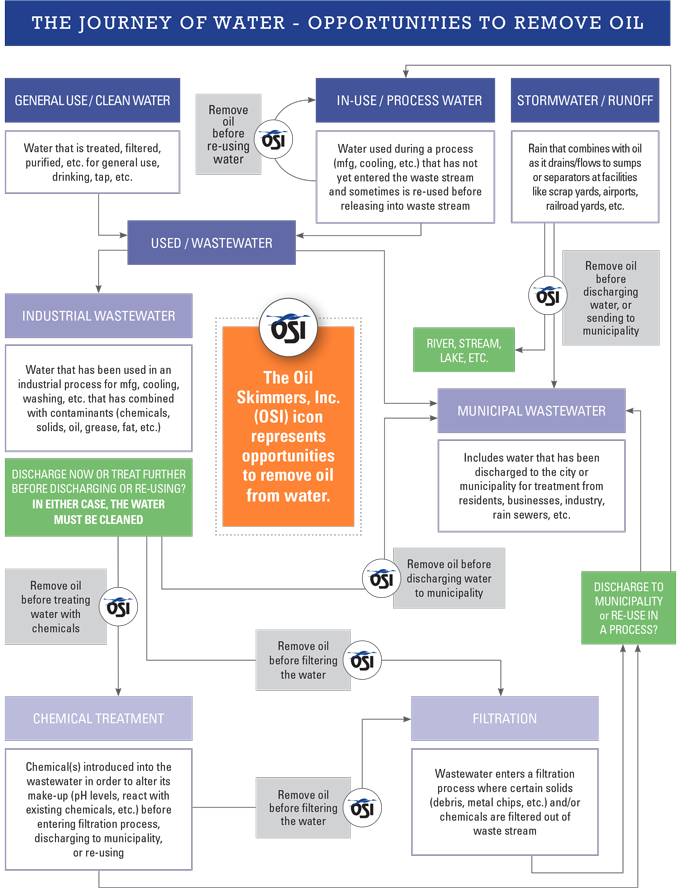

The infographic below demonstrates four key areas where oil skimming can be leveraged in the wastewater treatment process:

- Before process water is re-used for an industrial procedure.

- Before water is chemically treated.

- Before water is entered into a filtration system.

- Before water is discharged to a municipality.

Skim Early in the Wastewater Treatment Process

By removing the oil earlier in the wastewater stream, you can reduce costs and maximize efficiencies, as there is less likelihood of it clogging machines or filters. The earlier oil is skimmed, before it becomes emulsified or introduced to additional contaminants downstream, the better chance the oil can be recycled or reused.

Tube-type oil skimmers offer great flexibility and can be used to meet your wastewater treatment needs throughout the full water journey. Contact us today to discuss ways we can help you remove oil for significant operational and cost benefits.