%20(2).png)

Industrial oil skimming is a proven, efficient, and economical method to remove waste fat, oil, or grease (FOG) from wastewater. Removing waste oil is the first step in the water treatment process before the wastewater can be recycled, discharged, or further treated. The waste oil must first form a distinct layer, or separate from the wastewater, before adding an industrial oil skimmer into the application.

An industrial oil skimmer is a mechanical device generally operated by a pump or motor that removes fat, oil, or grease from wastewater (or other fluids such as coolant) after separation has occurred. Industrial oil skimmers help automate the first stages of the water treatment process and encourage the longevity of your wastewater, coolant or other fluids.

There are two categories of industrial oil skimming devices that will remove oil from water:

1. Selective Adhesion Industrial Oil Skimmers

Selective adhesion industrial oil skimmers are operated with a motor that circulates skimming media across the surface of the wastewater. The skimming media collects the waste oil and is transported to a collection vessel. Skimming media can come in a variety of materials such as rope, tube, belts, discs or drums. While the methodology is comparable, all skimming media are not equally proficient for certain situations, which means it is critical that you choose the right method for the task at hand.

2. Overflow Industrial Oil Skimmers

Overflow industrial oil skimmers are devices constructed with either a slot or gate that takes in the surface oil and is pumped or gravity drained to a collection vessel. Like selective adhesion oil skimmers, there are several types of overflow skimmers available to handle various applications.

We have put together a reference guide describing the types of industrial oil skimmers to equip you with the knowledge needed to make the right selection for your application. The following are the five different types of mechanically operated industrial oil skimmers that remove oil from water. Let’s examine the types of oil skimmers and how they work.

Types of Selective Adhesion Industrial Oil Skimmers

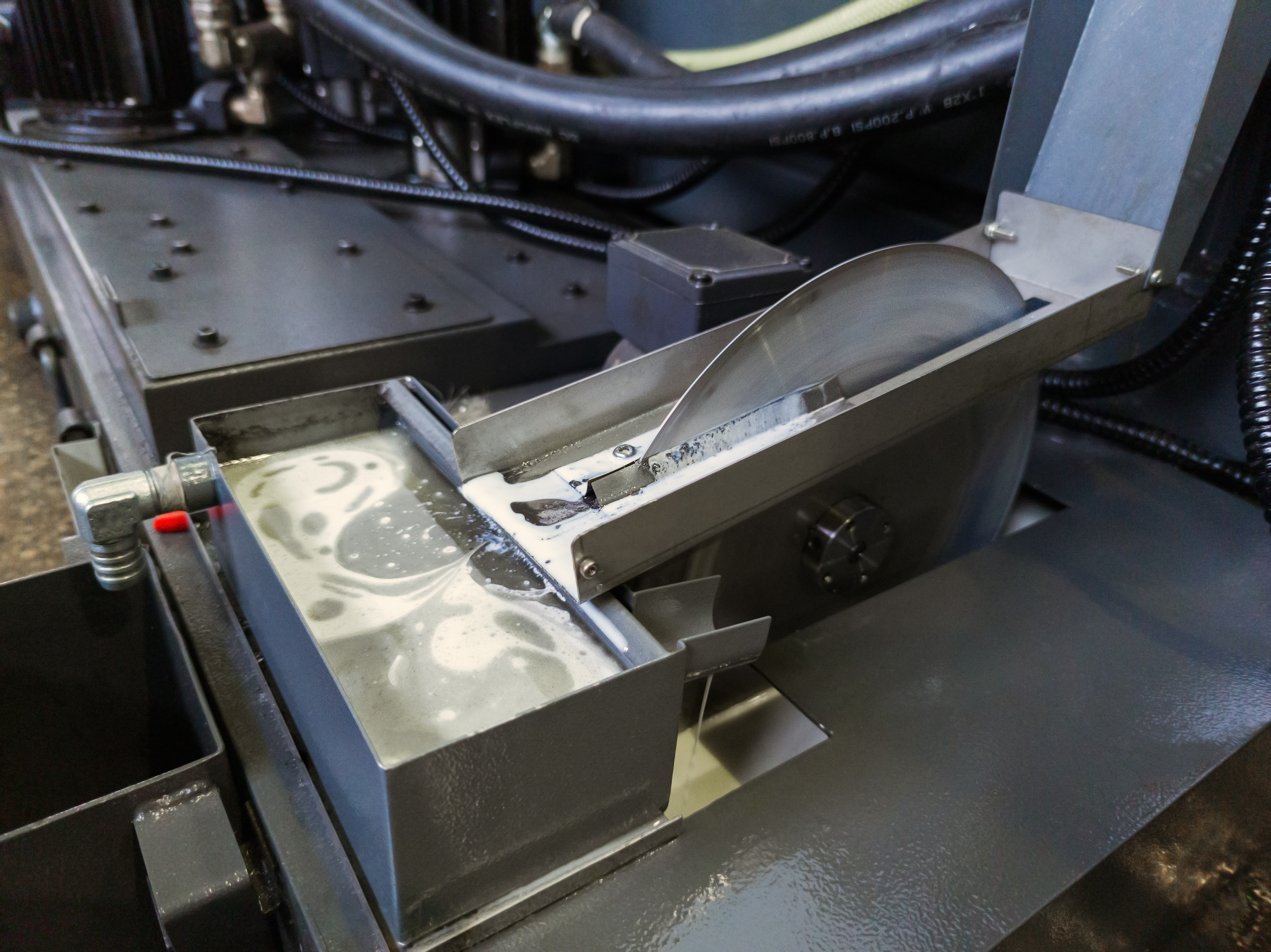

1. Belt Skimmers

Belts skimmers have a revolving strip, or belt, that rotates in a fixed path around a submerged pully, continually picking up the floating surface oil as it makes contact. The oil clings to the belt and is brought to a scraper that dispenses the oil waste into a trough leading to an oil storage tank. Belt skimmers tend to work better in areas with narrow, deep pits where lateral space is constrained. Due to the nature of the belt being fixed, the device is susceptible to debris interfering with the oil collection as it can create a dam around the fixed path, preventing oil from collecting onto the belt. The belt must be monitored to ensure that debris in the pond, pit or sump doesn’t prevent the oil from reaching the belt

Belts skimmers have a revolving strip, or belt, that rotates in a fixed path around a submerged pully, continually picking up the floating surface oil as it makes contact. The oil clings to the belt and is brought to a scraper that dispenses the oil waste into a trough leading to an oil storage tank. Belt skimmers tend to work better in areas with narrow, deep pits where lateral space is constrained. Due to the nature of the belt being fixed, the device is susceptible to debris interfering with the oil collection as it can create a dam around the fixed path, preventing oil from collecting onto the belt. The belt must be monitored to ensure that debris in the pond, pit or sump doesn’t prevent the oil from reaching the belt

2. Disk Skimmers

Disk skimmers are fixed devices that work by submerging the lower edge of a revolving disc(s) to collect the oil on the surface of the water. The oil is collected with a set of wiper blades and dispensed into an oil storage tank. These fixed skimmers are effective at collecting more oil than water. One drawback is there will be a drop in the pickup rate if the fluid level doesn’t cover at least half of the disk’s surface, making it ineffective in applications that experience water level or coolant level fluctuations.

Disk skimmers are fixed devices that work by submerging the lower edge of a revolving disc(s) to collect the oil on the surface of the water. The oil is collected with a set of wiper blades and dispensed into an oil storage tank. These fixed skimmers are effective at collecting more oil than water. One drawback is there will be a drop in the pickup rate if the fluid level doesn’t cover at least half of the disk’s surface, making it ineffective in applications that experience water level or coolant level fluctuations.

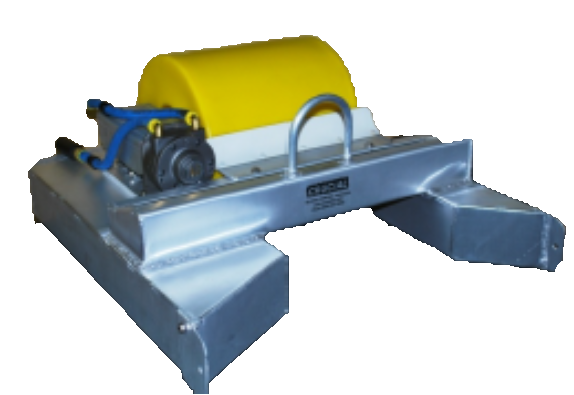

3. Drum Skimmers

Drum oil skimmers are fixed or floating devices that work by collecting surface oil on a revolving drum. The grooved drum collects the oil which gets scraped off and dispensed into a common sump, then pumped to an oil storage tank. Drum skimmers are durable and have the ability to collect light, medium and heavy oils. The fixed drum skimmer is sensitive to water level fluctuation and must be monitored closely to ensure contact. The fixed and floating drum skimmers are vulnerable to debris blockages.

Drum oil skimmers are fixed or floating devices that work by collecting surface oil on a revolving drum. The grooved drum collects the oil which gets scraped off and dispensed into a common sump, then pumped to an oil storage tank. Drum skimmers are durable and have the ability to collect light, medium and heavy oils. The fixed drum skimmer is sensitive to water level fluctuation and must be monitored closely to ensure contact. The fixed and floating drum skimmers are vulnerable to debris blockages.

4. Rope Skimmers

Rope skimmers typically follow a fixed path and work in a continuous loop to collect the floating surface oil. The oil collected on the rope is carried to a set of rollers that squeezes the oil waste into a trough to be drained into an oil storage tank. Rope skimmers require frequent monitoring for rope fiber deterioration, knots, and oversaturation. Because the rope follows a fixed path, similar to belt skimmers, monitoring is required due to the potential interference of debris blocking the oil from reaching the rope.

Rope skimmers typically follow a fixed path and work in a continuous loop to collect the floating surface oil. The oil collected on the rope is carried to a set of rollers that squeezes the oil waste into a trough to be drained into an oil storage tank. Rope skimmers require frequent monitoring for rope fiber deterioration, knots, and oversaturation. Because the rope follows a fixed path, similar to belt skimmers, monitoring is required due to the potential interference of debris blocking the oil from reaching the rope.

5. Tube Skimmers

Tube skimmers operate with a Free-Floating Collector Tube™ that continuously moves across the surface of water. The tube material is designed to attract floating fat, oil, or grease which adheres to the outside of the tube. The oil covered tube is then drawn through a set of scrapers and dispensed into an oil collection tank and the clean tube is then returned to the waste oil to collect more FOGs in a continuous fashion. The free-floating tube design enables the tube to snake around the water moving any debris aside to work seamlessly with little or no supervision, indoors and out. Designed for any environment and easy maintenance, tube skimmers can easily handle water level fluctuations and have no submerged mechanical parts.

Tube skimmers operate with a Free-Floating Collector Tube™ that continuously moves across the surface of water. The tube material is designed to attract floating fat, oil, or grease which adheres to the outside of the tube. The oil covered tube is then drawn through a set of scrapers and dispensed into an oil collection tank and the clean tube is then returned to the waste oil to collect more FOGs in a continuous fashion. The free-floating tube design enables the tube to snake around the water moving any debris aside to work seamlessly with little or no supervision, indoors and out. Designed for any environment and easy maintenance, tube skimmers can easily handle water level fluctuations and have no submerged mechanical parts.

Types of Overflow Industrial Oil Skimmers

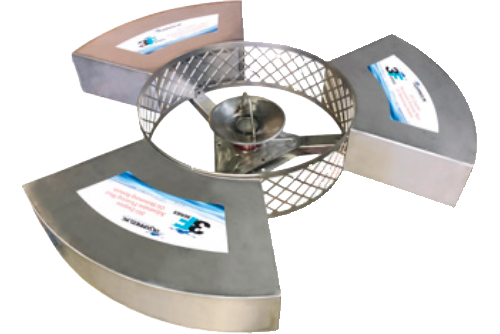

1. Weir Skimmers

A weir skimmer works as a floating device to remove oil or any floating material that has surfaced to the top of the water in areas such as sumps, above ground storage tanks, equalization tanks, oil/water separators, ponds, lagoons or open water. The oil floats over a lip into a trough and is transferred with a pump that is connected to a storage tank for recycling or disposal; if a pump is not present, the oil is gravity fed to the storage tank. Weir skimmers are a versatile floating method that can be deployed in multiple ways. While it is great for removing oil and other floating materials quickly, it will pick up more water than selective adhesion oil skimmers. Areas with varying water levels could interfere with the performance of the skimmer so it is important to properly calculate, specify and understand if the application experiences water level fluctuations before implementing a weir skimmer.

A weir skimmer works as a floating device to remove oil or any floating material that has surfaced to the top of the water in areas such as sumps, above ground storage tanks, equalization tanks, oil/water separators, ponds, lagoons or open water. The oil floats over a lip into a trough and is transferred with a pump that is connected to a storage tank for recycling or disposal; if a pump is not present, the oil is gravity fed to the storage tank. Weir skimmers are a versatile floating method that can be deployed in multiple ways. While it is great for removing oil and other floating materials quickly, it will pick up more water than selective adhesion oil skimmers. Areas with varying water levels could interfere with the performance of the skimmer so it is important to properly calculate, specify and understand if the application experiences water level fluctuations before implementing a weir skimmer.

2. Pipe Skimmers

Pipe skimmers are pipes fabricated with open slots that take in floating oil to gravity drain into a collection tank. Pipe skimmers span the width of an oil water separator and are typically designed into a system since it is challenging to retrofit a pipe skimmer after installation. The pipe requires continuous adjustment in either direction to avoid large amounts of water from being collected and is very sensitive to level fluctuations. Additionally, debris will easily clog the skimmer blocking its ability to collect the waste oil.

Pipe skimmers are pipes fabricated with open slots that take in floating oil to gravity drain into a collection tank. Pipe skimmers span the width of an oil water separator and are typically designed into a system since it is challenging to retrofit a pipe skimmer after installation. The pipe requires continuous adjustment in either direction to avoid large amounts of water from being collected and is very sensitive to level fluctuations. Additionally, debris will easily clog the skimmer blocking its ability to collect the waste oil.

Selecting the most effective oil removal device for your application not only helps your plant run better, but also makes good business sense. We understand each application is unique so we have oil removal experts who can provide you with a free application assessment and will recommend the best possible solution, whether or not it includes our equipment.

Start improving your oil removal operations today! Contact us to learn more about removing oil from water or read our blog, “Which Type of Oil Skimmer Works Best?”