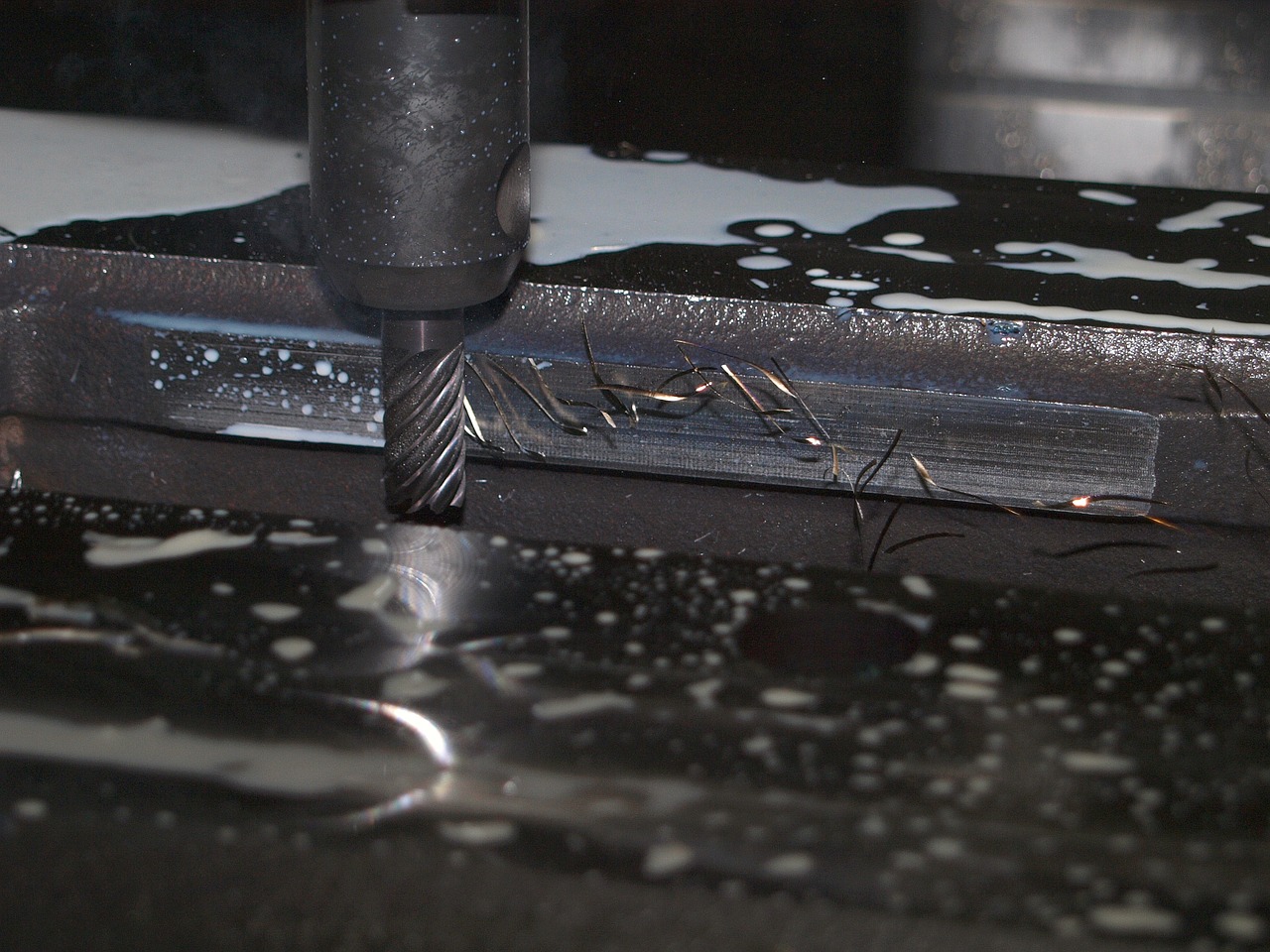

Waste oil is a common byproduct of a large number of processes.

Once oil enters your wastewater, it can have a negative impact on the health and safety of your

workforce.

Waste oil is a common byproduct of a large number of processes.

Once oil enters your wastewater, it can have a negative impact on the health and safety of your

workforce.

The Health Advantages of Skimming Oil

When oil lingers in waste or process water, it traps anaerobic bacteria, which can cause adverse health effects.

If left unchecked, this bacteria buildup results in foul odors in the workplace and can even cause skin disorders. In some cases, when waste oil isn’t removed early, the oil can come into contact with hot surfaces and produce a hazardous oily haze that workers unknowingly breathe in.

By consistently removing excess oil, you can both eliminate the bacteria that cause adverse skin conditions and stop hazardous oil vapor from forming in your work environment.

A simple solution is oil skimming—a process in which used oil is removed from the surface of waste and process water. Besides simply removing excess oil, skimming also prevents bacteria development by creating movement on the water’s surface as the oil is being removed. This movement fosters unfavorable conditions for bacteria growth both on and under the oil’s surface.

An Added Bonus: Boost Workplace Morale

By implementing oil skimming, you can improve workplace morale. After all, a work environment that smells bad leads to lower employee satisfaction and performance. What’s more, preventing the growth of anaerobic bacteria in waste and process water improves workplace health and safety by reducing the risk of skin and respiratory conditions.

A happy workforce is instrumental in running a successful business. Contact us today to employ oil skimming and improve the quality and health of your workplace.